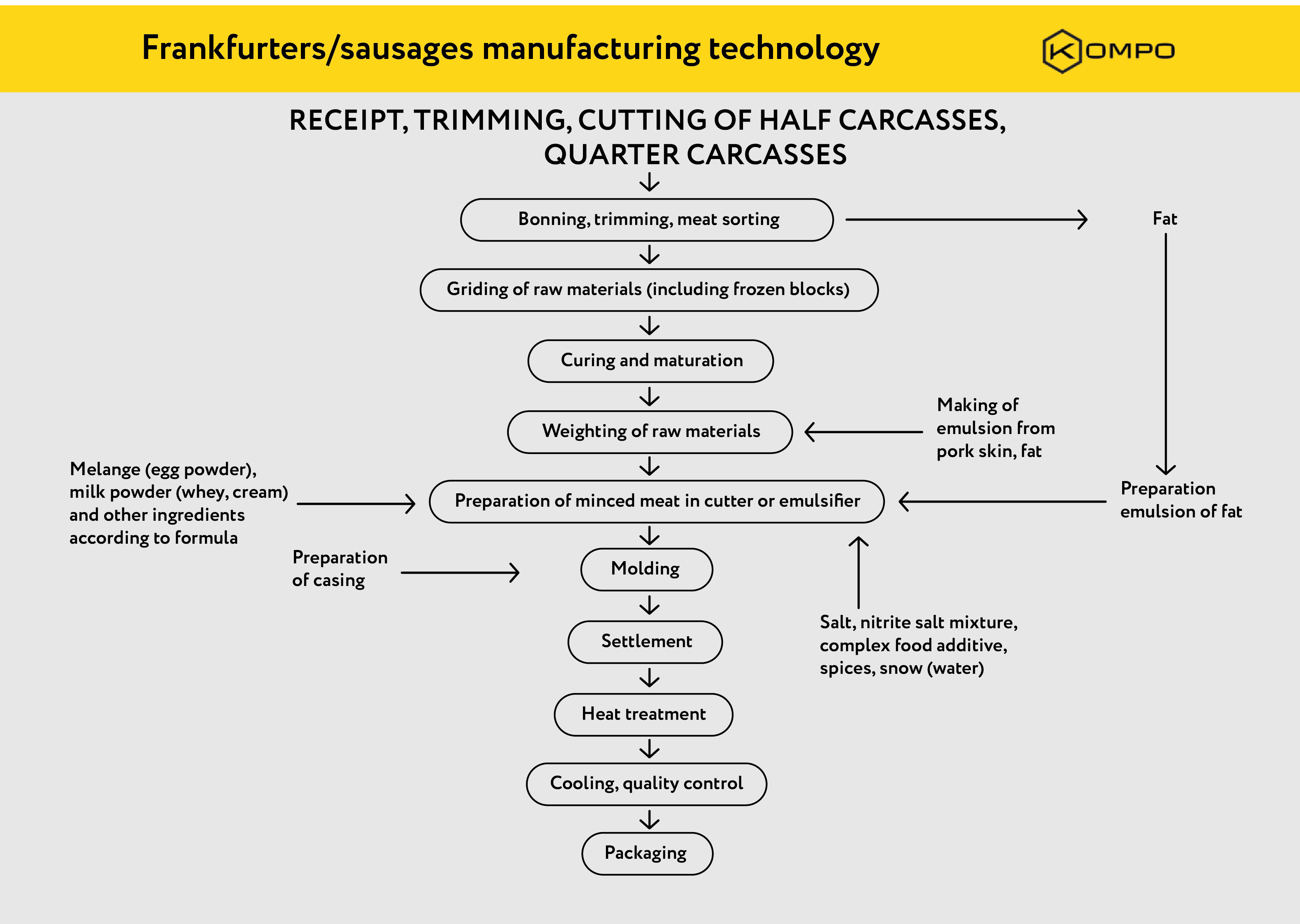

The technological scheme of frankfurters and sausages production is very complex. This is due to the variety of raw materials, additives and types of equipment used.

You can see the whole process on the diagram.

The final production result should be a homogeneous, fine-cut product that can withstand heat treatment without fat or water separation, has a dense consistency and good consumer characteristics.

The main raw materials used for production of frankfurters/sausages are beef, pork and poultry. Pork gives the product an elastic and smooth texture, but its use reduces the product density, while beef has a positive effect on texture and density, and also contributes to formation of an intense color when salted with nitrite.

The raw materials used for production of frankfurters/sausages can be either chilled or frozen. The temperature of chilled raw materials should be from 0 °C to 4 °C. Low temperature ensures slower bacterial growth and optimizes the solubility of the main myofibrillar proteins.

Trimmed meat raw materials, received in a chilled or frozen state, before making minced meat should be chopped and mixed with curing ingredients. Chilled meat raw materials are chopped in a mincer with a grid hole diameter 16-25 mm.

Frozen meat raw materials are chopped in a machine for flaking frozen food blocks manufactured by KOMPO (IB-4, IB-8) or in a machine for frozen product block grinding with a grid hole diameter of 16-25 mm. The chopped meat raw materials are mixed in a mixer with curing ingredients and sent to a chamber for maturation at 0 °C ÷ 4 °C. In the maturation process, the meat raw materials acquire a salty taste, stickiness (adhesiveness), resistance to microorganisms, and its water-holding capacity increases.

Frankfurter/sausage minced meat is prepared in a cutter or emulsifier. For this purpose, it is necessary to weigh the main and auxiliary raw materials, snow/water, and other ingredients according to the formula.

The amount of lean meat raw materials in the formula depends on the retention of added water, fat emulsification, texture formation, bite perception, color and taste of the product. Substitution of one type of meat for another, even if the mass fraction of muscle tissue is the same, results in products that differ in their characteristics.

Fat in the formula stabilizes the structure of the gel formed by dissolved protein, gives juiciness to the product and participates in formation of texture, and also helps to prevent protein compaction during cooking, acting as a filler.

Simultaneous emulsification of fat and binding of added water is a complicated process. During the process of making minced meat, it is necessary to dissolve as much protein as possible, since hydrated protein simultaneously binds added water and emulsifies fat. Hydrated protein creates a thin layer around finely ground fat particles, which prevents fat separation during heat treatment. The thickness of the protein layer covering the fat particles largely determines the stability of the emulsion - the thicker the protein layer, the more effective its stabilizing effect. The duration of cutting should be sufficient to activate as much protein as possible and to grind the fat so finely that its particles are not visible in the finished product.

The prepared frankfurter/sausage minced meat is unloaded from the cutter (emulsifier) and sent for molding.

In order to achieve high productivity (up to 1300 doses per minute when producing frankfurters weighing 50 g in polyamide casing), stable size (length, filling), weight of formed frankfurters/sausages, and for the purpose of process automation, it is recommended to form them on automatic (semi-automatic) sausage lines produced by KOMPO: vacuum filler KOMPO-MAXI 3000 (KOMPO-OPTI 2000 M) + sausage linker PLT-1000 (PLT-700) + automatic hanging device NU-270.

During the molding process the casing is filled with minced meat, twisted and sausage garlands are automatically hung on the hanging device. In the process of casing filling, minced meat is subjected to mechanical impact which adversely affects the state of emulsion. The stuffing horn used must have the maximum possible diameter for this type of casing. There must be no sharp edges or burrs on the outlet opening or on the inner surface of the stuffing horn as they can damage the protein layer covering the fat particles, which increases the risk of broth and fat pockets during heat treatment.

Casing overstuffing should be carried out in accordance with the manufacturer’s recommendations in order to obtain high-quality finished products without “wrinkles”, broth and fat pockets, as well as to prevent casing rupture during molding and subsequent heat treatment.

The control parameters located on the PLT-1000 (PLT-700) twister control panel allow you to set quickly and easily the required productivity, number of twists, casing filling, length of casing tails, number of sausages hung on the hook of the hanging device and other parameters necessary to obtain a high-quality product that meets the production requirements.

And thanks to automatic weight adjustment of frankfurters/sausages during molding on the PLT-1000 maximum dosing accuracy can be achieved and consequently reduce costs when producing fixed-weight products.

The formed sausage garlands are hung on sticks, put on frames, sent for short-term settling and subsequent heat treatment.

The heat treatment of frankfurters/sausages is carried out in universal heat chambers according to the approved heat programs. During the heat treatment process, the layer of activated protein containing externally introduced water and covering the fat particles denatures. This leads to fixation of water in the protein layer and stabilization of the fat particle in the three-dimensional matrix.

After the end of heat treatment frankfurters/sausages are sent for cooling to a temperature not exceeding 6 °C in the center of the product. To quickly reduce the temperature of the finished product, to avoid microbiological risks and to prevent the formation of “wrinkles”, cooling is first carried out under a shower in intensive cooling chambers. After showering, the final cooling of frankfurters/sausages is carried out in chambers with forced air circulation.

The cooled finished product is subjected to quality control by organoleptic and microbiological indicators, after which it is approved for further packaging and sale.