Grinding system KOMPO VP-6000

EQUIPMENT PURPOSE

VP-6000 is designated to obtain a clear pattern on cooked-smoked, dry, raw-cured sausages cut and under the casing. Attached grinder is adjustmented to any vacuum filler. It ensures presence of pieces of meat and fat of a certain size in the sausage stick due to the diameter of the installed outlet grinding plates and their uniform distribution over the entire cut. The range of permissible temperatures of minced meat is from -4 °С to +20 °С.

PERFORMANCE

Attached grinder ensures preservation of the vacuum filler capacity during operation with slightly frozen textured minced meat. For this, the device is equipped with a servo drive of a nominal power of 9 kW, which provides an optimal grinding performance. Attached grinder VP-6000 is recommended for large and medium-sized enterprises.

TECHNIcAL SPECIFICATIONS:

|

Model |

VP-6000 |

|

Output with free discharge, kg/h, min * |

6000 |

|

Power supply, V/Hz |

400/50 |

|

Power consumption, kW |

9,0 |

|

Grid diameters, mm Grid with inclined hole diameters, mm |

1,5; 2; 2,5; 3; 3,5; 4; 4,5; 5; 6; 7,8; 10; 13 3; 4; 5; 6 |

|

Dimensions, mm: Length*Width*Height |

840*850*1390 |

|

Net weight, kg |

350 |

* Measurements were made with a rotary vacuum filler KOMPO-MASTER 1100.

GRINDING UNIT

Attached grinder VP-6000 can be used with three types of grinding units:

- Receiving grinding plate → knife → intermediate grinding plate → knife → output grinding plate

The classic version which is used for production of all types of structured sausages with a cut size of maximum 8 mm, allowing for high-quality, gentle grinding of minced meat to the required fraction.

- Receiving grinding plate → knife → intermediate grinding plate → knife of special design → output grinding plate

A set for trimming which allows to remove all hard inclusions from minced meat (cartilage, tendons and bone fragments).

- Receiving grinding plate → knife → output grinding plate

It is used in production of cooked sausages and structured sausages with a cut size of 8 mm or more.

OPERATION OF THE ATTACHED GRINDER

Attached grinder operates with the filler only. Any screw-type or rotary-type filler that provides the filling pressure required for grinding (minimum 20 bar) can be used as a pumping device. VP-6000 has its own control panel, but to use the full potential of functional capabilities of the device it is necessary to use KOMPO sausage fillers.

Attached grinder is aggregated with a filler. A clipper or nozzle is connected to the outlet pipe for production of portioned "curly" minced meat. For manual forming of sausages, a cog is installed on VP-6000 outlet pipe.

When using VP-6000, minced meat for structured sausage should be minced coarser in the cutter. The filler feeds minced meat into the nozzle of the attachment grinder from where it enters the grinding unit, which consists of a set of grinding plates and knives. Under the pressure created by the filler, minced meat pieces are pressed into the plate holes and cut off with a cutting knife. As a result, minced meat is obtained with evenly chopped and kneaded pieces with the diameter of the holes in the outlet plate of the grinder.

GRINDING FUNCTIONS: |

|

|

|

|

|

CONTROL PANEL

VP-6000 is equipped with a seven-inch touch control panel which allows it to be operated with pumping devices from different manufacturers. Intuitive interface. Programs with parameters for grinding products can be saved in the memory of the grinder. Clickable buttons are sized conveniently for staff wearing rubber gloves.

MINCED MEAT PRESSURE SENSOR

The minced meat pressure sensor makes it possible to reduce wear of the ВП-6000 grinding unit. The pressure value is displayed on the control monitor. The knife shaft starts rotating only after filling the chamber with minced meat in front of the grinding unit and creating the required pressure on the plate. Accordingly, there is no dry friction of the knives on the plates.

It becomes possible to control the grinding process. On the same minced meat, the pressure during normal grinding is in a certain range and if this range is exceeded, then it is necessary to stop the process and eliminate the cause of the deviation.

MINCED MEAT TEMPERATURE SENSOR

A temperature sensor built in the VP-6000 working area with visualization of the value on the control monitor ensures that the drive stops when the set temperature parameter is exceeded. This prevents production of defective products (ground meat, porosity on the cut), encourages workers to comply with the production technology.

SEPARATOR

Separator is designed to remove non-food or low-value inclusions from minced meat (connective tissue, cartilage, tendons, bone fragments). For additional trimming of inclusions, it is necessary to install a knife of a special design in the grinding set, mount a cut-off valve on the branch pipe for removing inclusions and set the necessary settings on the monitor.

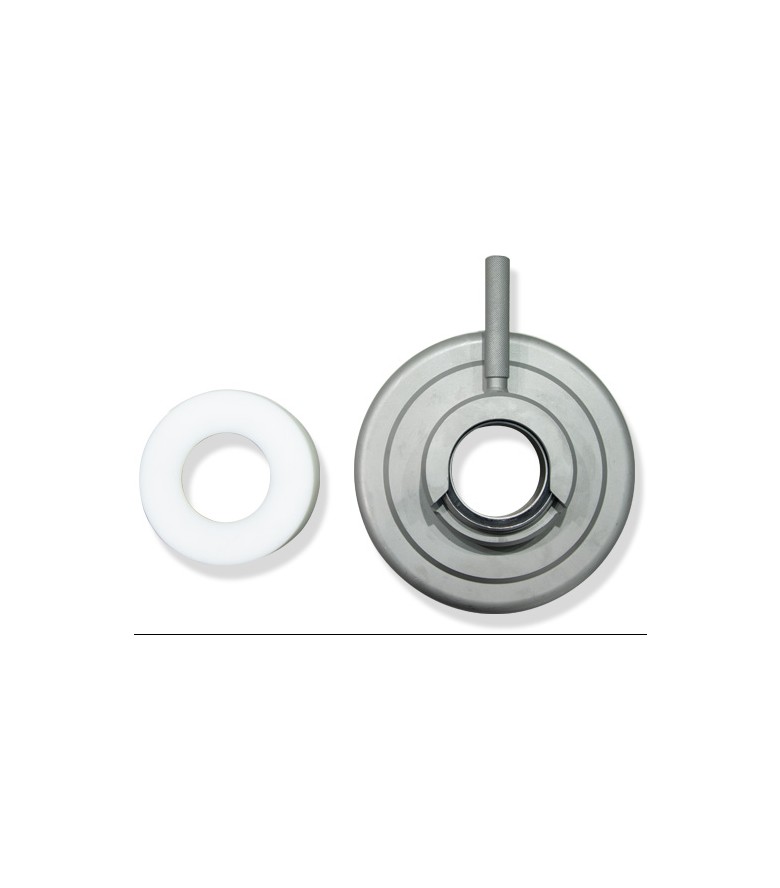

RANGE OF GRINDING PLATES

It is possible to purchase a wide range of grinding plates with hole diameters: 1,5; 2; 2.5; 3; 3.5; 4; 4,5; 5; 6; 7,8; 10; 13 mm.

Diameters of grinding plates with inclined holes: 3; 4; 5; 6 mm.

When determining necessary grinding plates, it is important to understand the regularity: the output grinding plate is selected according to the required size of minced meat pieces on the sausage cut. The intermediate plate is selected according to the size of the output plate and must have a hole diameter twice the diameter of the outlet plate hole. To obtain a high-quality grinded product, the size of the minced meat pieces loaded into the filler hopper should be twice as large as the diameter of the holes in the intermediate plate.

video:

ADVANTAGES: |

|

|

|