Precise doser machine KOMPO UTD-01

EQUIPMENT PURPOSE

Precise dosing machine UTD-01 is used for an increased accuracy of dosing during production of boiled sausages, pastes, processed cheese and other fillings with past-like consistency without any inclusions at cut. Used with screw fillers and automatic clippers KOMPO only.

SANITARY TREATMENT

All units in contact with the product are quick-detachable without the use of special tools, which ensures high-quality washing and disinfection of the product.

- Increases line productivity

- Dosing accuracy

- Work with all kinds of pasty products

technical specifications:

| Model | UTD-01 |

| Dose range adjustment, gr | 100 - 1000 |

| Dose precision, % | ± 1 |

| Air consumption per working cycle, liters | 1,82 |

|

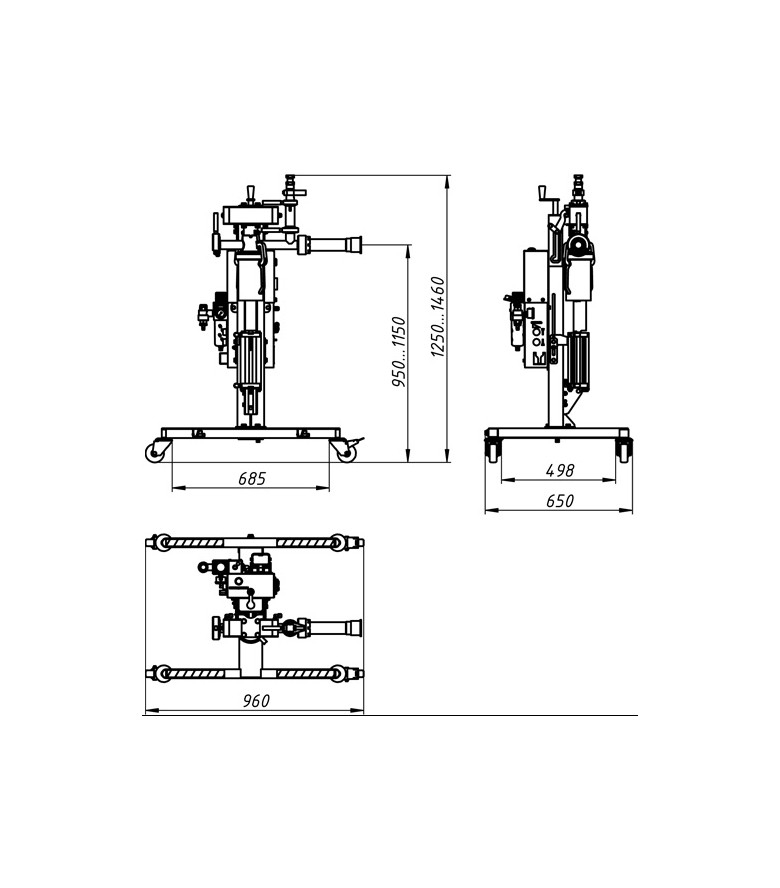

Dimensions, mm: Length*Width*Height |

960*650*1460 |

| Net weight, kg | 85 |

OPERATION OF THE MACHINE

The machine performs volumetric dosing by filling the cylinder with minced meat and its further pushing with the piston with pneumatic drive into the clipper cog. The dose size is adjusted by turning the adjusting handle and consists in changing the cylinder volume (the distance from the piston to the top of the cylinder).

The machine is compatible with the filler. The clipper feeder is connected to the UTD outlet. Control signals from the UTD to the filler and clipper are transmitted by means of electric cables. The equipment line the filler + UTD + the clipper is maintained by one worker.

At the beginning of the process, a special slide valve that redirects flows of minced meat is in the position of filling the product into the cylinder. The filler starts feeding minced meat into the cavity of the UTD cylinder. Simultaneously, the piston starts moving downwards creating additional suction effect. When the piston reaches the bottom dead center, a sensor is actuated which gives the command to the slide valve actuator to turn to the unloading position and the piston to move upwards, pushing a dose of minced meat into the clipper cog. The clipper forms a stick and delivers it to the technological table. The operator makes a control weighing of the formed stick and, if necessary, adjusts the dose by turning the adjusting handle. After setting the dose, the line switches to automatic operation.

PRECISE DOSING

The use of UTD makes it possible to ensure dose repeatability with an accuracy of +/- 1%. Dosing accuracy is connected with and depends on presence and uniformity of air distribution in the filler, stability of the filled casing diameter, correct selection of the diameter of the cog and brake unit to the diameter of the casing used, stability of the clipper operation.

To obtain an optimal result, it is necessary to ensure high-quality vacuumizing of minced meat in the cutter, use special casing splitters which allow using the casing brake unit with a passage diameter as close as possible to the nominal casing diameter, comply with the manufacturer’s requirements for casing preparation.

To achieve maximum dosing accuracy, it is necessary to observe the dependence of the required stick weight and the minimum possible casing diameter:

|

Nominal diameter (caliber) of the casing, mm |

Stick weight range, gr |

| 40 | 170 - 1000 |

| 45 | 240 - 1000 |

| 50 | 330 - 1000 |

| 55 | 440 - 1000 |

| 60 | 570 - 1000 |

| 65 | 720 - 1000 |

| 70 | 900 - 1000 |

| 75 | 1000 |

| 80 | - |

DOSING CYLINDER

Possible options of dosing units with 500 ml and 1000 ml liners. 1000 ml liner ensures dosing within all range of weight from 100 gr to 1000 gr, but more precise weight adjustment during production of, for example, 200 gr stick, is possible when 500 ml liner is used.

ADVANTAGES: |

|

VIDEO: