The PLT-1000 is equipped with a mechanism for automatic feeding of the casing to the stuffing horn.

On the PLT-1000, the control panel is located in the linking area, where the operator is most likely to work. This allows line parameters to be set directly from the operator's workstation. Unlike our competitors, there is no need for the operator to move to the vacuum filler console during operation. The operator is immediately informed of malfunctions and incorrect operation by means of an illuminated linker status display on the control panel.

PLT-1000 has a protective cover made of Plexiglas to protect the operator from moving elements.

The PLT-1000 can be combined with the hanging device NU-270 and together with it forms an automatic sausage line. Since the operator is not distracted when putting the casing on the line, continuous operation of the line is possible. Pauses in work only for loading of a new batch of casings into the accumulator, loading of minced meat into the filler hopper, and recharging of casings.

Actual productivity, which is confirmed by the results of tests 1000 doses per minute on sausages weighing 50 g in polyamide casing at 3.5 twists sausages and 1300 doses at 2.5 twists and other similar parameters. I would like to emphasise that we are talking about actual performance and not some technical / theoretical performance, which is usually indicated in catalogues.

As with the PLT-1000 and other models of rollers on the market, the actual performance will vary depending on:

- the casing used;

- the weight of the sausage;

- the number of twists;

- filler capacity.

Another important parameter for a sausage line is dosing accuracy. Experienced professionals know that the dosing accuracy depends on many factors, and the influence of the linker on it may not be the most decisive. To ensure accuracy, the vacuum filler with which the linker works, the minced meat and casing used are also important. Plus many other factors. For our part, we can say that when the PLT-1000 is working with an KOMPO OPTI 2000 filler with VV series screws, the dosing accuracy can reach up to 1 g per sausage. These are the results obtained during tests at meat processing plants.

The PLT-1000 can work on emulsified and structural minced meat, using polyamide, collagen and cellulose casings.

For the convenience of the operator on PLT-1000 a number of functions are realised:

- Stopping after a set number of portions.

- Adjustment of the number of twists of the first and the last sausages.

- Synchronous work with the hanging device.

- Filling of the centrepiece with minced meat at the start of operation.

- Counter of the portions produced.

- Automatic stop of the line at the end of casing.

PLT-1000 can be optionally equipped with a washing gun. This allows to quickly clean the twister from minced meat residues during operation.

PLT-1000 provides high accuracy of portioning by length and weight. This is achieved thanks to the use of linker mechanism. Formation of sausage in linker mechanism is based on separation of minced meat filled in the casing by separating blades. As the distance between the separators is fixed, all sausages have the same length.

The PLT-1000 linker mechanism is driven by a servo drive, which ensures more stable operation. Similar competitor models use asynchronous drive. Installation of linker belts is quite fast and takes a few seconds. Pneumatic cylinders pre-tension the belt, which prevents it from falling off during installation. After installation, the pneumatic cylinders automatically tension the belts to the required level. This solution is a patented KOMPO innovation.

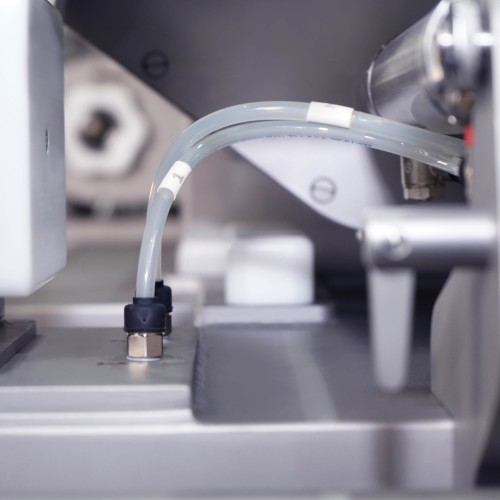

In-line installation is very convenient. A minimum number of tools are required. The curved metal piping allows levelling the height difference between the vacuum filler and the twister, as well as unevenness of the shop flooring, without significant height adjustments of the equipment.

The PLT-1000 is compact enough in size and weight to allow it to be moved around the workshop by a single employee.

A wide range of chain sets allows to produce products with diameter from 16 to 38 mm.

The PLT-1000 as well as the PLT-700 can be combined with vacuum fillers not only from KOMPO but also from other manufacturers. For this purpose the linker can be equipped with appropriate cables for connection to vacuum fillers, including those of other manufacturers.

The casing feeding to the stuffing horn is realised with the minimum necessary number of actuators, which simplifies service and reduces the risk of potential breakdowns and incorrect operation of the device. In our competitors this mechanism is realised in a much more complicated way.

International Sausage Day is celebrated around the world on 13 November.

Sausages are widespread and can be found in every cuisine in the world. Sausages can be boiled, fried, stewed, eaten raw, added in sliced form to other dishes in pizza, used in barbecues, stuffed, twisted into mincemeat.

Common dishes made with sausages include:

- sausage in dough

- hot-dog

- pita-dog

- pancake-dog

- corn-dog

- sausage-ppang

The KOMPO PLT-1000 linker helps you to create sausages of different lengths and thicknesses, with different casings and recipes.