Vacuum filler KOMPO OPTI 2000M

EQUIPMENT PURPOSE

Vacuum screw sausage filler KOMPO OPTI 2000M is designed for stuffing and dosing of boiled and structured sausages, frankfurters, small sausages, liver and blood sausages and pastes. The patented design of the filling pump units allows obtaining a finished product characterized by solidity, dense consistency, without pores and voids.

The use of screws of a special design in combination with ATTACHED GRINDER VP-6000 guarantees a high quality of the pattern of cooked smoked, semi-smoked, raw-smoked and dry sausages in the level of rotor fillers.

Temperature range of minced meat processed varies from -4°С to +60°С.

DESIGN

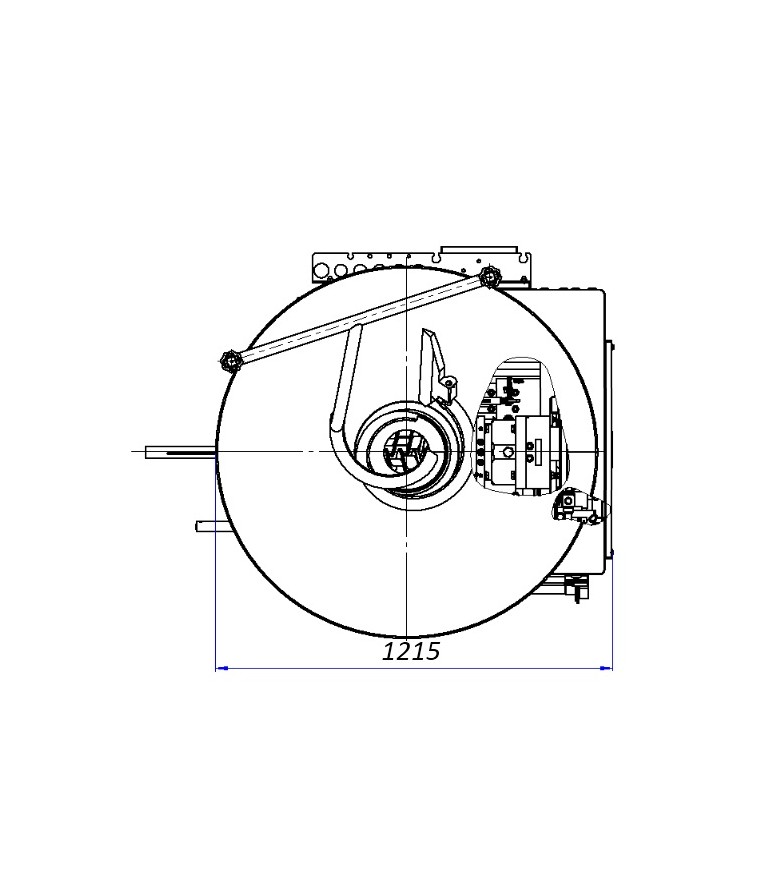

The vacuum filler consists of the housing (with asynchronous electric motor with frequency converter, twin-screw pump with gearbox, electrical cabinet, minced meat collector of the vacuum system, agitator drive, twisting device drive, vacuum pump), on which are mounted: hopper for minced meat collection (with active and reactive agitators), LCD control panel, knee switch and ladder for hopper cleaning.

UPGRADED KOMPO-OPTI 2000М USES:

- Vacuum system with vacuum programmable adjustment

- Heavy-duty agitator for operation with structured minced meat

- 11 kW electric motor

SAFETY

To ensure safe operating conditions, the filler is equipped with work blocking sensors:

- when the hopper is retracted

- when the nozzle of the displacer housing is removed

- when the ladder for servicing the hopper is unfolded

- High dosing accuracy

- Output:

14 000 kg/h - Operation with structured minced meat

output

- The vacuum filler is recommended for medium and large-scale enterprises.

- Theoretical output of the filler in pump mode is up to 14000 kg/h.

- The actual output when working with clippers depends on the operator’s activity (stopping to put the casing on the filling horn), the horn diameter, the diameter of the casing to be filled, the length of the sausage sticks, the clipper speed (clipping the casing filled, pulling the jaws, application of the clips, sticks cutting).

TECHNIcAL SPECIFICATIONS:

| Model | 2000M |

| Agitator in hopper | + |

| Column loader FCD | option |

| Linking device | option |

| Minced meat temperature mode | from -4 °C |

| Theoretical output, kg/h | 9000 - 14000 |

| Rated supply voltage, V | 400 |

| Dosage range adjustment, gr | 10 - 9999 |

| Hopper capacity, l | 250 |

| Distance from the floor to the horn axle, mm | 1020 ± 20 |

| Output power, kW, maximum | 11 |

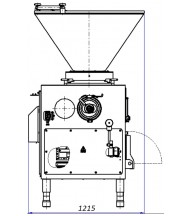

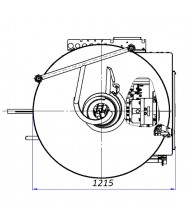

| Overall dimensions, mm: Length*Width*Height |

1215*1215*2080 |

| Net weight, kg | 695 |

METHODS FOR PRODUCING SAUSAGE PRODUCTS

For production of frankfurters and small sausages in common with vacuum filler a linking device FPK or the frankfurter line is used where the filler performs the function of a pump for minced meat.

SAUSAGE STICKS CAN BE PRODUCED ON THE FILLER IN THE FOLLOWING WAYS:

- Operation on direct filling. The corresponding cog is installed on the filler. A casing is put on the cog (hose casing, or prepared sections). The filler stuffs the casing. The operator manually forms a sausage stick by twisting it; knitting; application of clips using manual clippers KN-6R, KN-7R, pneumatic single clippers KN-3S, KN-4S, pneumatic double clippers KN-21M or formed on the small sausage tying machine.

- Operation with pneumatic, semi-automatic and automatic clippers. The clipper (KN-22S, KN-23S KN-24P, KN-26P, KN-201, KN-32, KN-501) is connected with the filler. The casing is put on the clipper cog. The filler stuffs minced meat into the casing at the signal from the clipper. The clipper twists the casing filled, applies the clips, loops and cuts the formed stick. It is possible to adapt the filler for operation with a clipper of any manufacturer.

To improve quality of pattern on cut and under casing of structural sausages (cooked smoked, semi-cooked, raw-smoked, dry) it is necessary to use special screws together with VP-6000.

OPERATION

The filler is served by one operator. When using the filler with the linking device or clipper, one operator is able to service both devices. Additional workers will be required to suspend formed sausage sticks on the smoking frames.

The clipper, linking device or the cog for direct filling is connected to the filler. Minced meat is loaded into the hopper with a loader. The operator selects one of four operating modes in the control panel menu:

- Manual. The dose value is set by the time the knee switch is pressed.

- Single. The dose value is set using settings on the control panel, and to deliver it, it is necessary briefly press the knee switch.

- Automatic. Mode for operation with the clippers. The dose is set in the settings and is delivered taking into account the configured pauses, upon a signal from the clipper.

- Twisting. Mode for operation with the linking device FPK.

Then the required parameters are set: dose value, filling speed, vacuum depth, agitator speed. Minced meat under the action of vacuum created by the vacuum system and screws, when minced meat is pushed out, and under its own weight, is pulled into the working area, where it is picked up by the screws, partially vacuumized and moved to the unloading area, from where it is filled into the casing through the cog.

LOADING HOPPER

LOADING HOPPER

The clipper is equipped with 250 l loading hopper. Active (spiral with a scraper) and reactive (spiral guide) agitators are mounted in the hopper.

The task of the active agitator is to clean the lower part of the hopper from minced meat and to stabilize uniformity of minced meat supply to the screws.

The task of the reactive agitator is to direct the flow of minced meat, pushed by the active agitator, into the receiving area of the screws.

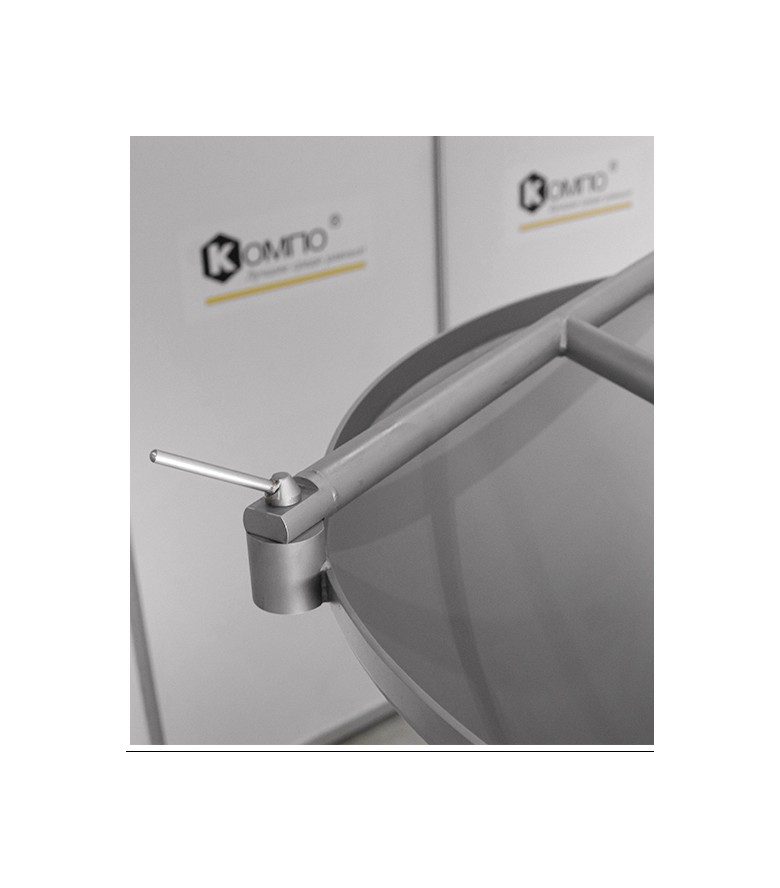

In the upgraded KOMPO-OPTI 2000M, fixation of reactive spiral is changed to ease access and maintenance.

Convenience of cleaning the hopper when switching to another type of product and during its sanitary treatment is provided by a folding ladder with three steps, thanks to which even a small operator gets full access to the hopper.

OPTIONS OF DISPLACER SCREWS

OPTIONS OF DISPLACER SCREWS

8 screw variants can be supplied as an option.

Each of the screw variants has its own purpose for use in production of certain types of products: small sausages, frankfurters, boiled or structural sausages. The use of newly designed screws allows significantly increasing the dosing accuracy, performance and quality of work on structural minced meat. The set of displacer screws is selected individually depending on the requirements of the customer based on the terms of reference. The terms of reference determine the list of products that are planned to be produced on a vacuum filler, their main characteristics and requirements for dosing accuracy, performance. To increase the service life of the screws and the displacer housing in the upgraded filler, a support grid is used which prevents contact between the displacer housing and the screws during operation of the filler.

vacuum system

The vacuum system of the filler serves to suck minced meat from the hopper into the screw pump, while additionally the air trapped in minced meat in the cutter is partially removed. The vacuum depth can be adjusted and is selected empirically by the operator for each type and fluidity of minced meat.

KOMPO OPTI 2000М uses an advanced vacuum system with program control.

The required operating mode of the vacuum system can be chosen on the control panel:

- "Constant vacuum". Vacuum depth is set and this parameter is constantly automatically maintained both during operation and during stops of the filler. When processing liquid minced meat in this mode, minced meat cab be sucked in the minced meat collector when the filler stops, which reduces efficiency of the vacuum system.

- "Vacuum+". This mode is used when working on liquid minced meat. Vacuum is applied only during the operation of the filler. During downtime, it is absent and the minced meat is not pulled into the minced meat collector. This allows, at the start of the filler operation, to establish a vacuum of a given depth and significantly reduce the number of pores in minced meat.

ASSORTMENT OF horns

For direct filling operation, horns of diameter of 10, 19, 23, 29, 35 mm are available. If it is necessary to improve the pattern under the casing of cooked smoked, raw-smoked sausages, it is possible to use a rose-horn with a diameter of 29 mm. The option of manufacturing horns of other diameters is possible.

CUT-OFF LIMITERS AND MINCED MEAT DIVIDERS

When processing minced meat of cooked sausages prone to pore formation, in order to obtain a decent result, it is necessary to use the minced meat cut-off limiter in the hopper, which task is to increase the contact area of the minced meat with the vacuum zone for greater efficiency of the air removal. The type of the cut-off limiter for each type of minced meat is selected based on experience.

One more way to eliminate pores is the use of minced meat dividers and stabilizers, which due to a sharp multiple change in the direction of minced meat flow, make air bubbles separate into smaller fractions that are invisible to the eye. There is a large assortment of minced meat dividers with different sizes of through holes (7, 9, 10, 11, 12, 14, 15 mm), which allows, based on experience, selecting the required option in which there are no pores and voids in minced meat, and loss of the filler performance is minimal.

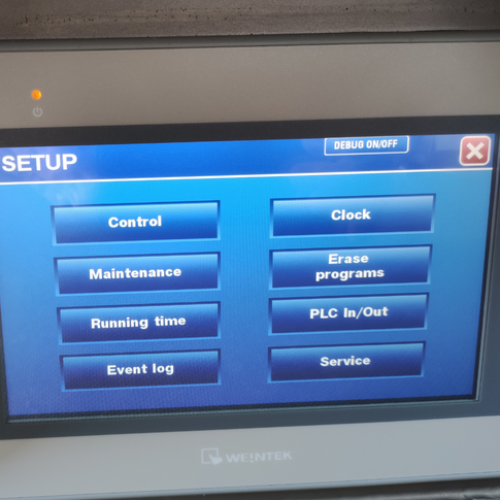

CONTROL SYSTEM

The filler is equipped with 7-inch touch screen LCD monitor. The size of the clickable menu icons is optimized for comfortable operation by the operator wearing rubber gloves. The menu interface is simple and intuitive. The filler can store up to 384 programs with parameters for each product. A protective screen is installed on the control monitor to protect it from external influences.

THE FOLLOWING ADDITIONAL FUNCTIONS ARE IMPLEMENTED IN KOMPO OPTI 2000М SOFTWARE:

- Storage of vacuum setting in the filler memory for various types of minced meat

- Reduced vacuum

- Pre-clipping

- Back suction

LOADING DEVICE

Column loader FCD is used for loading minced meat in the hopper.

Assembly, disassembly, washing and storage of dismountable parts of the filler are carried out on a special technological trolley, where each part has its own place.

ADVANTAGES: |

|

|